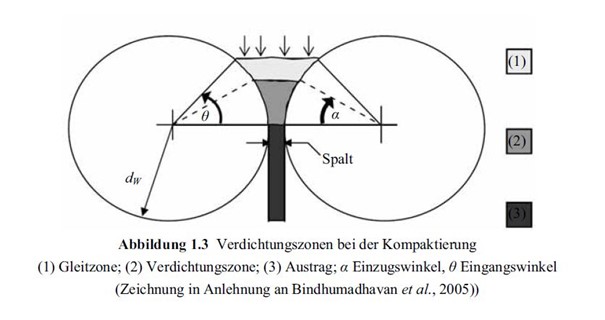

To illustrate the complex and physical events in the compression unit a roller compactor, it helps not to consider the powder column above the gap as a whole, but they see consists of infinitely many individual layers of powder before. To simplify the description, the area across the gap, which is filled with powder, first of all divided into two areas.

The first area is an area in which the rolls slide therethrough under the powder. This is called the sliding zone accordingly. Here you can learn the little powder compaction due to the narrowing space. The rearrangements in the powder bed lead to a denser packing, but without powder particles to agglomerate there. At this point, the powder particles are still present separately. The entry into the slit starts at the moment by the friction force which is transmitted by the rolling motion on the particles, is greater than the normal force. This area which is directly adjacent to the sliding zone, characterized by the feeder angle.

The rolling speed of roller compactor, as well as the roll diameter has no significant impact on the collection angle. Mainly due to the powder characteristics, the catchment behavior is affected.

From this time, the powder layers are compacted to such an extent that they exert a force on the roll, as they are forced into a smaller volume. The further the powder is compressed, the greater the increase in force. The maximum compressive force is reached just before the narrowest nip and then falls rapidly. If you add up all the forces exerted by the individual layers of powder on the surface of the roll, you get the total power expended in the gap, that is the force which must be applied by the machine for compacting needs.

In Figure 1.3, the processes in the gap during the roller compaction are summarized schematically. The space between the rollers can be divided into three zones.